Overview and Specifications of WheelTop's Affordable Electronic Groupset "EDS"

This article summarizes the features and specifications of the budget-friendly electronic groupset "EDS" newly released by the Chinese manufacturer WheelTop.

Posted at: Feb 13, 2023

When looking for items to upgrade your road, MTB, or gravel bike tires, technical terms such as TPI, compound, and pattern appear in the descriptions. At first glance, tire specifications may seem difficult to understand, but if you keep only the important details in mind, your tire selection will be enhanced.

Table of contents

Sponsored Link

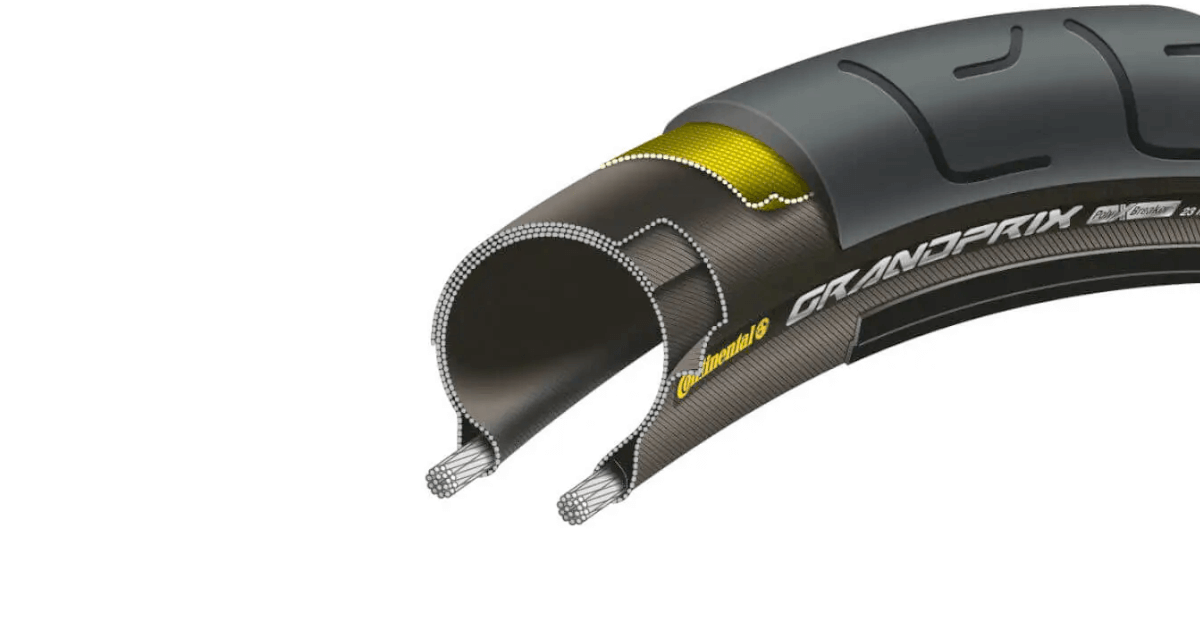

The “tread” of a bicycle tire refers to the external material where the tire meets the ground. It is only the external tread that is black at a quick glance and that most people recognize as the tire.

Since the tread is in direct contact with the road surface, it is the part of the tire that shows its character. The material used for the tread changes the grip and rolling resistance, and the grooves on the surface, called the “tread pattern,” change how the tire responds to wet road surfaces.

The tread, along with the compound described below, also protects the tire’s internal structure, such as the casing and inner tube.

The part of the tread that is placed on the ground and is mixed with reinforcing agents and anti-cracking agents is called the compound. The material of the compound changes the puncture resistance and resistance to cracking.

In a durable tire for long rides, the compound is made of a stronger and thicker material to increase durability, but this increases the weight of the tire.

The balance between these two factors is what makes a tire unique to each manufacturer and model. However, since each manufacturer often claims to use “proprietary materials and technologies,” it is difficult to compare the performance and characteristics of tires based on compound alone, unless you have considerable knowledge of tires.

A bicycle tire is roughly divided into two parts: the rubber tread surface, which is the “surface” that touches the ground, and the casing, which is the “back surface” that maintains the shape of the tire.

Although it is easy to assume that bicycle tires are made entirely of rubber, in fact, bicycle tire casings are often made of woven nylon. You may have seen fraying coming out of old, neglected bicycle tires. That is a condition where the fibers of the casing have come out.

The casing is the part that maintains the shape of the tire and can be called the skeleton of the tire. Therefore, it is the part that greatly affects the character of the tire itself.

Not only what material is used for the casing, but also the density of the fibers woven into the casing is important. The density of the casing is used as an indicator of the TPI, which will be discussed later.

However, some manufacturers use a special layer between the casing or casing and tread to improve puncture resistance.

In the case of tubeless tires, since the tire itself holds air instead of a tube, there is an “air seal layer” on the surface of the casing (inside the tire) to prevent air from escaping through the casing or compound.

The part of the tire that bonds the tire to the wheel rim is called the bead.

City bicycles, for example, use a “wire bead” with a metal wire in the bead area. Road bicycle tires use Kepler fiber or other materials instead of metal wire in the bead section to reduce weight. Since the tire can be folded because it is not made of metal, it is sometimes called a “foldable” tire.

Naturally, fiber wires are lighter than metal wires, which has a significant impact on the overall weight of the tire.

In addition, beads are a part to be aware of when using tubeless tires, and the word “bead” is often used in terms of whether or not it is possible to “raise the bead” to make the wheel and tire adhere to each other, and whether or not air leaks are likely to occur with tubeless tires.

The type of bead is an easy part of choosing a bicycle tire to understand.

Just remembering that “wire beads are low-cost, heavy tires” and “tires with fusible Keplerian fibers are expensive and light tires” is one indicator when choosing a tire.

Of course, some folderable tires are heavy and do not necessarily have to have Kepler fiber beads, but if you are more particular about tires, it is best to choose tires with non-wire beads, which are as light and high quality models as possible.

Aside from slick tires and road tires that often have thin grooves, tread pattern is very important for gravel and MTB tires.

Tread patterns can be broadly divided into three patterns.

Tread pattern affects the ability to catch the road surface.

If a tire has knobs, it will scrape the road surface well even with sand and mud, but the tire will be heavier and rolling resistance will increase. Tires without knobs, like slicks, cannot draw sand or mud out and will get stuck if it gets in, but the lower rolling resistance allows for a lighter ride on the pavement.

Slick tires are basically chosen for road bikes, while block tires are chosen for MTBs, which are designed to be ridden on unpaved roads. Semi-slick tires are popular for gravel road bikes, which assume both.

Conversely, you can put semi-slick tires on a road bike to make it look more gravel-like, or you can put slick tires on an MTB to customize it to light city riding specifications.

Thus, the tread is a major determinant of the direction of the tire.

TPI stands for Thread Per Inch and is a unit that measures the amount of fiber in the casing material. A typical road bike tire will often have a TPI of 120 to 150, but some tires have a TPI of 220.

The denser the casing (higher TPI), the more flexible and lightweight it is, and the lower the rolling resistance, but the durability of the casing is reduced because each fiber is thinner in order to increase density over the same area.

Conversely, a lower TPI tire is more durable because “lower density = thicker fibers,” but the casing is stiffer, making the tire slightly harder to drive.

In other words, when selecting a tire, checking the TPI is an indicator to determine “how strong (durable)” the tire is.

As for TPI, it is also a part of the balance between “whether to take lightness or durability,” so manufacturers design the best ratio for each model.

Therefore, it is difficult to say that “high (low) TPI is not necessarily good”.

Sponsored Link

Overview and Specifications of WheelTop's Affordable Electronic Groupset "EDS"

This article summarizes the features and specifications of the budget-friendly electronic groupset "EDS" newly released by the Chinese manufacturer WheelTop.

What Is Shimano Shadow RD? Features and Benefits

What is Shimano’s Shadow RD used in their latest rear derailleurs? This article explains its features and the benefits of choosing Shadow RD.

[MTB / Hybrid Bike] Hydraulic Brake Manufacturers for Flat Bars

An overview of manufacturers that produce hydraulic brakes for flat-bar MTB and hybrid bikes, along with their key features. Also includes tips on how to choose the right flat-bar hydraulic brake brand.

Shimano Chain Compatibility for Road, MTB, and Hybrid Bikes

An overview of Shimano chain compatibility across road bikes, mountain bikes, and hybrid bikes. Includes guidance on how to choose the right chain for your drivetrain.

Shimano ESSA Lineup and Compatibility with Existing 8-Speed Parts

An overview of Shimano's newly released 8-speed component group "ESSA" and its compatibility with existing 8-speed parts.

SRAM Cassette Compatibility Guide

Compatibility guide for SRAM cassettes used in road and MTB bikes. Find matching drivetrains and wheels easily.

Compatibility Guide for SRAM MTB Components

A detailed explanation of compatibility between SRAM MTB components. This guide outlines which parts can be used together and which combinations are not compatible.

Road and MTB Sprockets Compatibility Overview

A guide to the compatibility between road and MTB sprockets, explaining whether they can be used together with different components.

Types of Shimano Di2 Tools and Their Compatibility

A guide to the essential Shimano Di2-specific tools, especially the "plug tools" used for connecting components, and their compatibility with various Di2 parts.

Shimano CUES Cassette Compatibility Guide

A detailed guide to the compatibility of Shimano CUES series cassettes. Includes an overview of compatible rear derailleurs, chains, and wheels.

Shimano Hydraulic Brake Hose and Connector Standards Guide

An explanation of the differences between Shimano’s hydraulic brake hoses BH90 and BH59, the types of connecting bolts, and how to choose the right hose for your brake system—including key points to watch out for.

[By Manufacturer] Types, Features, Pros and Cons of Hydraulic Brake Oils

This article explains the types of hydraulic oils used in bicycle hydraulic brakes, their characteristics, and the brake oil types used by each manufacturer.

Types and Compatibility of Shimano Di2 Batteries

The Di2 battery is the core of the Shimano Di2 system, influencing the overall system layout. This article explains the different types and their compatibility.

Shimano Di2 Wire Types and Compatibility

Overview of Shimano Di2 electric wire types and their compatibility with Di2 components.

How to Identify Shimano Di2 Generations

Explains the generational differences in Shimano Di2 components and their compatibility. Includes a list of component series and their corresponding generations.

In-Depth Guide to Shimano 12-Speed Cassette Compatibility

A detailed explanation of the key compatibility factors when using Shimano's 12-speed cassettes—specifically the required wheel (freehub) and drivetrain, which differ significantly from previous 11-speed systems.

Perfect Guide to Shimano 11-Speed Cassette Compatibility

A detailed explanation of two key compatibility factors when using Shimano 11-speed cassettes: the required wheel (freehub) and drivetrain.

Perfect Guide to Shimano 10-Speed Cassette Compatibility

A detailed explanation of two key compatibility factors when using Shimano 10-speed cassettes: the required wheel (freehub) and drivetrain.

In-Depth Guide to Shimano 9-Speed Cassette Compatibility

A comprehensive explanation of two key compatibility factors when using Shimano 9-speed cassettes: the required wheel (freehub) and drivetrain.

What Is a BOOST Crank? Differences from Standard MTB Cranks and How to Choose

This article explains what a BOOST crank is, how it differs from conventional MTB cranks, and provides guidance on selection across different manufacturers.